Let’s talk about what factors impacts Tea Tree Oil's shelf life.

- Choice of packaging

- Storage temperature

- Oxidation potential

The Australian Tea Tree Oil Industry (ATTIA) has published a white paper compiling the extensive research on factors affecting the stability of 100% Pure Australian Tea Tree Oil. This document provides an excellent reference guide, clarifying many recurring questions about proper storage conditions to achieve an optimal shelf life.

So what affects the long term stability of Tea Tree Oil?

Read on...

We have summarized ATTIA’s White Paper below.

[Download the full ATTIA White Paper on Stability of Tea Tree Oil HERE]

Choice of Packaging

Amber glass vs Clear glass

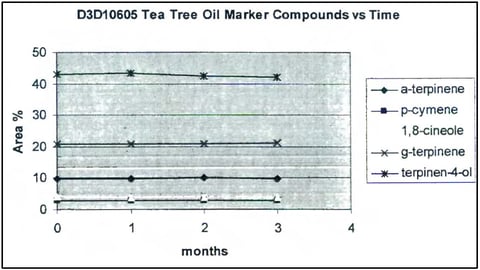

A 3-month study assessing the stability of pure Australian Tea Tree Oil in clear glass retail bottles was initiated to investigate shelf life stability. The trial used accelerated (40°C) and real time retail-shelf conditions – both of which included exposure to fluorescent light. The results demonstrate no perceptible difference in Australian Tea Tree Oil quality or constituent values in the clear glass packaging.

These data overcome the common perception that amber glass must be used for maintaining the stability of Tea Tree Oil. Clear glass is safe for use.

Small retail packaging (up to 100 ml)

ATTIA has conducted a research with Tea Tree Oil in 100 ml amber bottles for 12 months at 25°C, under simulated use daily use conditions. The results have shown that the peroxide level increased gradually over time however the oil maintained stable and safe for use. Therefore, ATTIA recommends that Tea Tree Oil stored in amber bottles (up to 100 ml) and intended for retail consumer use should have the expiry date set at 1 year from when first opened.

Bulk storage packaging

ATTIA’s Code of Practice quality system requires member-producers to use one of the following packages to store bulk quantities of Pure Australian Tea Tree Oil:

- Stainless steel drums

Uncoated aluminum flasks with PTFE wadding

Uncoated aluminum flasks with PTFE wadding- level 5 fluorinated HDPE containers

- Schütz IBC line specifically designed for Tea Tree Oil

Each container must be tightly sealed and with a COP tamper evident seal (drums and IBCs).

Sparging the headspace

It is highly recommended to sparge the headspace of these storage containers with either Nitrogen or Argon gas to exclude air. The sparging technique will assure no exposure to air (oxygen). While not noted in the White Paper, Argon is considered superior to Nitrogen as it has a molecular weight of 39.9 atomic units. As Oxygen is 16 atomic units, Nitrogen (14) will dissipate as soon as the cap is removed from the container.

|

ATTIA’s recommended shelf life is 3 years. However, controlled shelf life studies of bulk Tea Tree Oil demonstrate the shelf life may be extended for as much as 10 years if the Tea Tree Oil is stored properly, according to ATTIA guidelines. |

Storage Temperature

Many products are demonstrated to be affected by storage temperature, including foodstuffs and manufactured goods. Certainly there should also be a greater risk to the long term stability of pure Australian Tea Tree Oil.

While the recommended storage temperature for Tea Tree Oil is ‘ambient temperature’, typically observed to be between 20˚C and 25˚C. However, this is not always practical nor probable with such bulk quantities being shipped and stored around the world. As such, extended shelf life studies have demonstrated that, when stored in properly specified containers (see above), Tea Tree Oil can maintain its integrity at storage temperatures of up to 40˚C for an extended (2+ years) period of time.

|

ATTIA recommends that wherever possible TTO should be stored under stable conditions, preferably at or below 25°C. |

Oxidation Potential

ATTIA highly recommends lab sampling Australian Tea Tree Oil if in doubt of its quality or at the approach to the stated shelf life. The Tea Tree Oil should be tested against the international standard ISO 4730: 2017 Essential oil of Melaleuca, terpinen-4-ol type (Tea Tree oil). The levels of terpinen-4-ol, , α-terpinene, γ-terpinene, terpinolene, and in particular, ρ-cymene, will indicate potential levels of oxidation.

While not a parameter of the ISO standard, peroxide value limits have been determined through published studies. These studies indicate that Tea Tree Oil should have a peroxide level less than 9 meq O2/kg.

Down Under Enterprises is proud to support the Australian Tea Tree Oil Industry Association, supplying only ATTIA certified Code of Practice Tea Tree Oil. This is your third-party guarantee that Down Under’s Tea Tree Oil is produced, distilled, packed, and stored according to the COP guidelines.

Down Under Enterprises is proud to support the Australian Tea Tree Oil Industry Association, supplying only ATTIA certified Code of Practice Tea Tree Oil. This is your third-party guarantee that Down Under’s Tea Tree Oil is produced, distilled, packed, and stored according to the COP guidelines.Contact us HERE if you have any questions or want to enquiry about our Code of Practices Australian Tea Tree Oil.

2 Comments